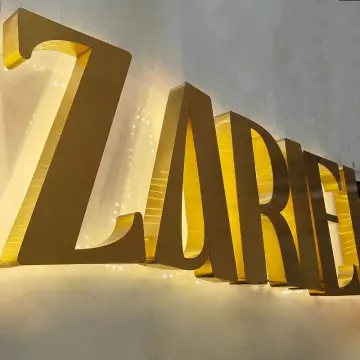

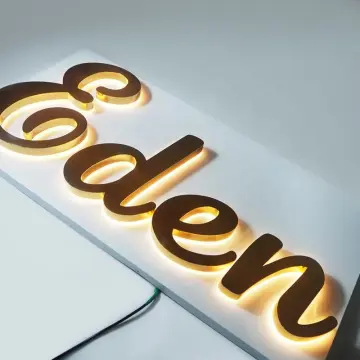

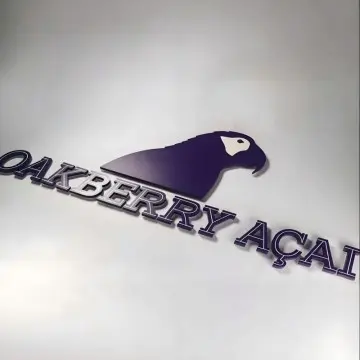

Solid Acrylic Backlit Letters Crystal Edge 3D Illuminated Sign

Let’s talk about what powers the sign. A huge mistake rookie sign makers make is maxing out the power supply. If a sign draws 100 watts, they buy a 100-watt transformer. That is a recipe for failure. We strictly follow the "80% Load Rule." If your backlit letter set requires 80 watts of power, we will install a 100-watt or 120-watt driver. We never let the transformer run at full capacity. This "headroom" keeps the electronic components cool and prevents the backlit letter from flickering or burning out the power unit during a hot summer heatwave.

Installation speed is another factor that costs you money. Traditional signage requires the electrician to strip, twist, and tape wires for every single character. That takes hours. We speed this up by pre-installing "Wago" style quick-connectors or waterproof male-female plugs on the back of each backlit letter. Your installer simply clicks the wires together like building a Lego set. This doesn't just save on labor costs; it means if you ever need to remove a single backlit letter for cleaning or painting the wall, you can unplug it in two seconds without cutting any hard wiring.

Finally, we have to consider wind load during installation. Paper templates are fine for small indoor signs, but if you are installing a large backlit letter outdoors on a windy day, a paper pattern rips apart. For larger projects, we offer the option of a semi-rigid PVC plotting template or a plywood stencil. This rigid guide ensures that the mounting holes for every backlit letter are drilled with millimeter precision, even if the wind is blowing. It ensures your sign is perfectly straight, because once you drill into stone or cladding, there is no second chance to fix a crooked backlit letter.

Case Picture