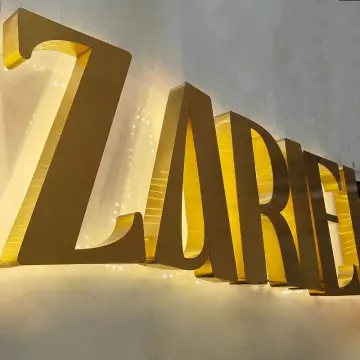

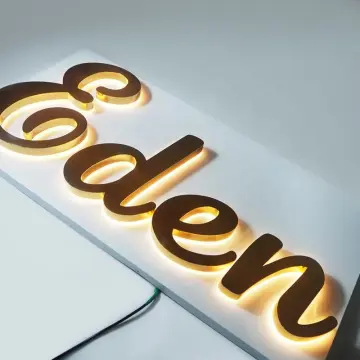

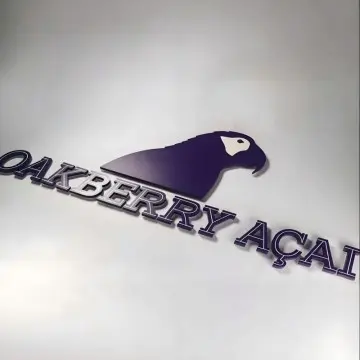

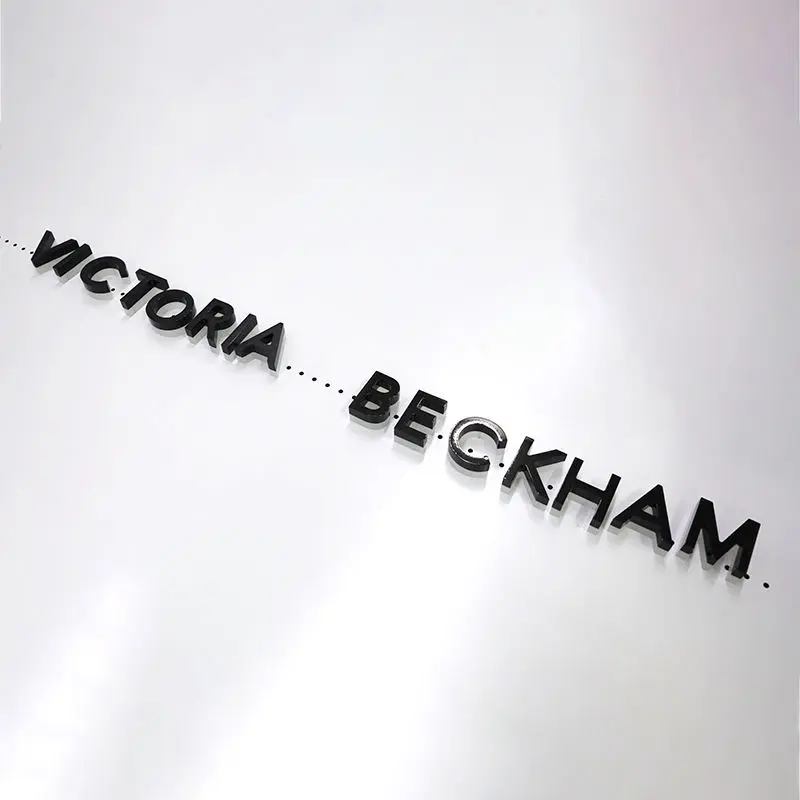

Solid Acrylic 3D Backlit Letters with Crystal Side Illumination

Most factories run out their drivers at maximum power. A sign that requires 100 watts receives a transformer of 100 watts. This causes the driver to get hot and fail within one year. The backlit letter systems we design have a headroom of 20% as a buffer. A backlit letter set that consumes 80 watts has a driver of 100 watts industrial. This maintains the cooling of parts, eliminates flickering in voltage spikes, and greatly prolongs the life of the entire electrical system.

Waterproofing is often misunderstood. A "Waterproof LED" (IP65) can still fail if the backlit letter shell traps humidity inside, creating a "sauna effect" that rots the circuit board. We don't just seal everything shut; we create "Active Ventilation." We drill tiny, baffled weep holes at the lowest point of each backlit letter. These holes allow condensation to drain and air to circulate while the "baffle" prevents insects and direct rain from entering. It’s the difference between a sign that lasts three years and one that lasts ten.

Finally, look for "Light Leak" or "Halos on the Face." Sometimes, light from the LEDs inside a backlit letter will bleed through the metal returns or the front edges, making the sign look "glowy" in places it shouldn't. To achieve a perfectly crisp, professional look, we apply a secondary coat of "Block-out Black" paint to the inside walls of the backlit letter shell before applying the final exterior color. This internal shielding ensures that 100% of the light is directed out the back, creating a sharp, high-contrast halo without any messy light spilling through the seams.

Case Picture