rushed Silver Backlit Office Signs Reception Wall LED Letters

Another major difference in our process is how we seal the back. Most shops just cut a flat piece of acrylic and glue it to the edge. That is cheap, but it often leaks water. Instead, we use a CNC machine to carve a "step" or "groove" into the thick acrylic back panel so it slots perfectly inside the metal shell of the backlit letter. This creates a mechanical lock, almost like a puzzle piece. We then use small side screws to secure the back of the backlit letter, which means the seal is tighter against rain, yet you can still open it up for service ten years down the road. We also need to talk about the wire that connects everything. When installing a backlit letter on a stone or glass facade, hiding the cable is a nightmare. A thick black cable ruins the floating illusion. To solve this, we use a specialized, translucent silver-plated wire for the power feed. It is thin but tough, and it reflects the surrounding colors, making the wire almost invisible to the naked eye against light-colored walls. It is a small detail, but it prevents the "spaghetti wire" look that can make a backlit letter installation look messy.

Finally, there is the issue of color consistency, known in the industry as "binning." Nothing looks worse than one backlit letter appearing slightly pink while the next one looks slightly green. We buy our LEDs in tight "MacAdam Step 3" batches. This guarantees that every single chip matches perfectly. Whether you order a sign today or need a replacement backlit letter five years from now, we ensure the color temperature is an exact match. We build these to be permanent architectural assets, not just temporary decorations.

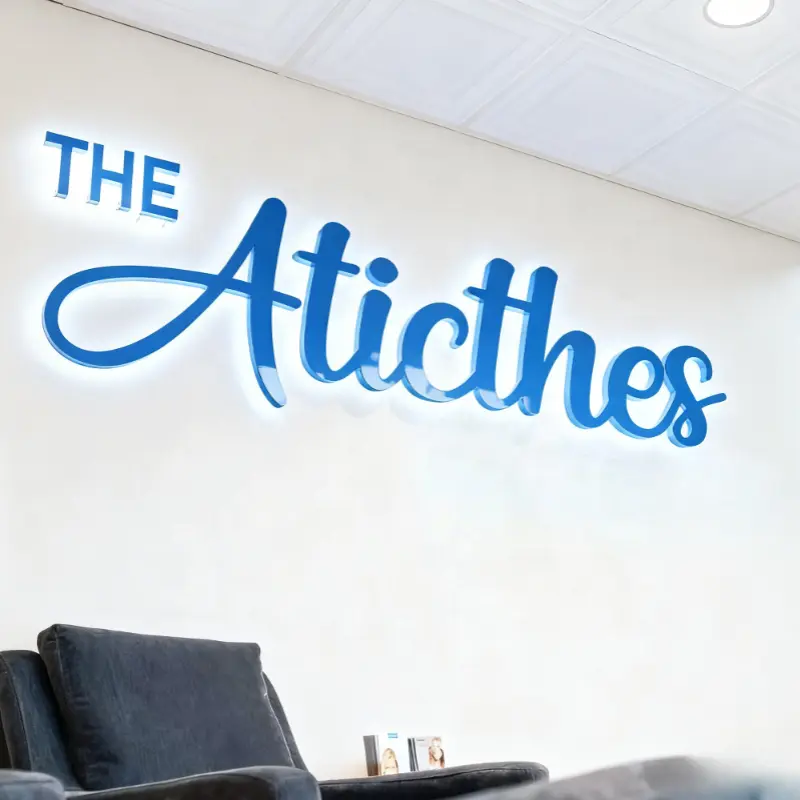

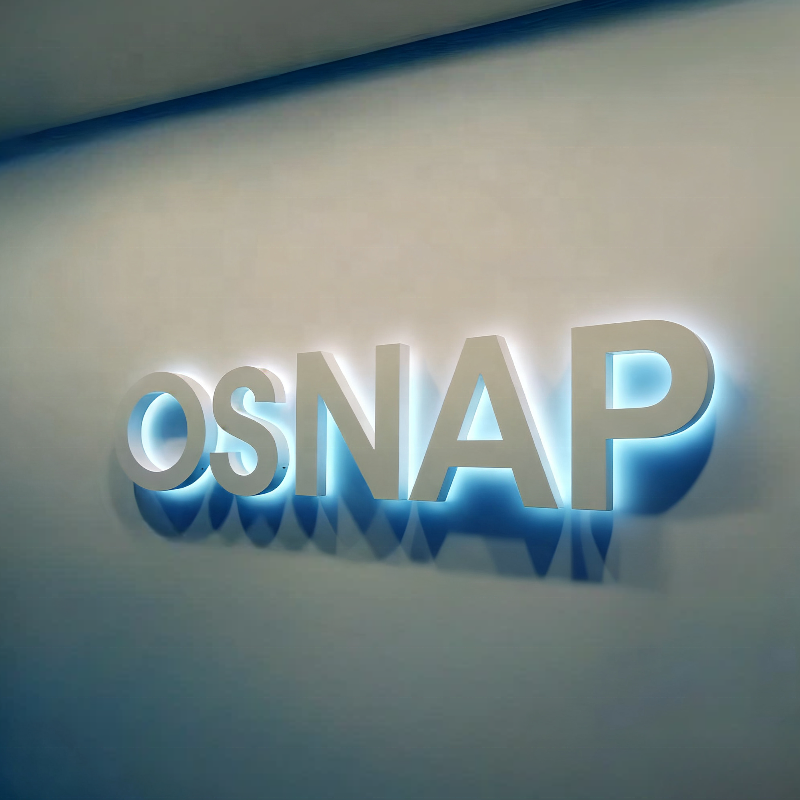

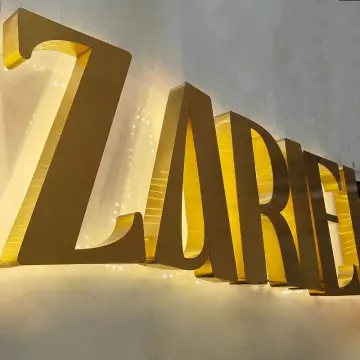

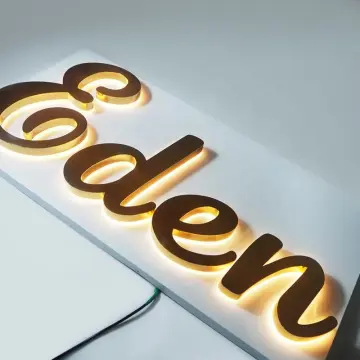

Case Picture