Premium Rose Gold Stainless Steel Backlit House Numbers for Home

Electrical shorts are the number one cause of fire in signage. When a power wire passes through the metal back of a backlit letter, it rubs against the sharp raw edge of the aluminum. Over time, wind vibration cuts the insulation, causing a short circuit. We install a protective rubber grommet or a plastic bushing in the cable exit hole of every single backlit letter. It acts as a cushion, ensuring the wire insulation never touches the sharp metal edge, keeping your building safe from electrical faults and tripping breakers.

Maintenance access is something most designers forget. Imagine trying to fix a connection, but the installer pulled the wire so tight inside the wall that you can't pull the sign off. We always instruct installers to leave a 6-inch "Service Loop" of extra cable coiled inside the backlit letter or pushed into the wall cavity. This slack allows a technician to pull the backlit letter away from the facade to inspect the connections comfortably without having to cut the wires or dismantle the entire wall.

Finally, let's talk about color saturation. If you want a red halo, many shops will just use white LEDs and put red vinyl on the back. This looks washed out and pinkish. We use native colored LEDs (Red, Blue, Green, Amber) for any colored backlit letter. A native Red LED emits a specific wavelength (around 625nm) that punches through the acrylic with far more intensity and richness than filtered white light ever could. It makes the backlit letter glow with a deep, saturated color that demands attention.

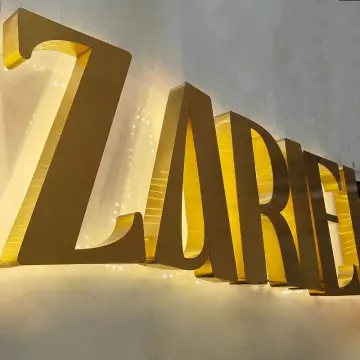

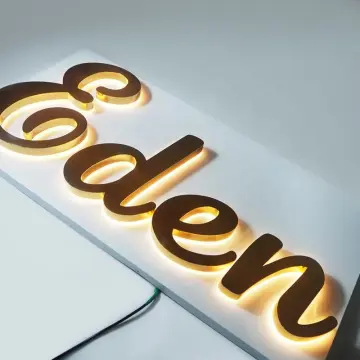

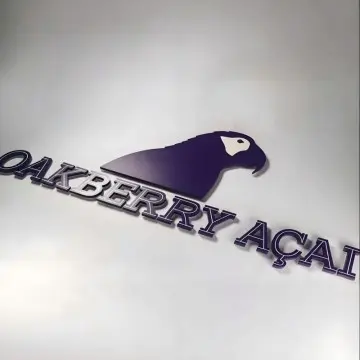

Case Picture