LED luminous signs: A complete guide to energy-saving upgrades and efficient installation in commercial spaces

Driven by rising energy costs and tightening environmental protection policies, LED luminous signs are rapidly replacing traditional neon and fluorescent signs and becoming the preferred solution for commercial space lighting signs.

Six energy-saving advantages of LED luminous signs

- Energy consumption comparison:70% electricity saving compared to traditional light sources

At the same brightness:

LED luminous sign power consumption: 12W/㎡

Neon sign power consumption: 45W/㎡

Fluorescent sign power consumption: 38W/㎡

- Lifespan advantage: 50,000 hours of ultra-long service life

The lifespan of conventional LED modules is 8 times that of neon lamps, reducing maintenance frequency by 80%.

- Precise light control: effective utilization rate increased by 40%

Traditional light sources 360° scattered light vs LED 120° directional light emission, reducing the risk of "light pollution" complaints.

Actual measured data: The luminous flux utilization rate of LED luminous signs reaches 85%, while that of neon lamps is only 35%.

- Low-temperature operation: 90% reduction in heat dissipation energy consumption

LED operating temperature is less than 50℃, no additional heat dissipation system is required, while traditional light sources require cooling devices.

- Environmental compliance: Zero mercury materials are RoHS certified

Comply with EU REACH regulations to avoid recycling costs caused by mercury pollution in fluorescent lamps.

- Intelligent control: Can be combined with light sensing/time control modules

Support automatic dimming (30% brighter on cloudy days) and time-based brightness switching, further saving 15%-25%.

Technical specifications for the entire process of LED luminous sign installation

1.Preparation before installation: structural load-bearing measurement, circuit safety verification (LED luminous signs need to be equipped with leakage protection switches separately), and waterproof level selection (indoor humid areas must meet IP54 standards, and outdoor signs must use IP67 protection levels).

2.Key steps for on-site installation: such as frame fixing, line layout, translucent panel installation and control system debugging, etc.

3.Acceptance and maintenance standards: brightness uniformity detection, fault emergency plan, periodic maintenance

Typical scenario application solutions

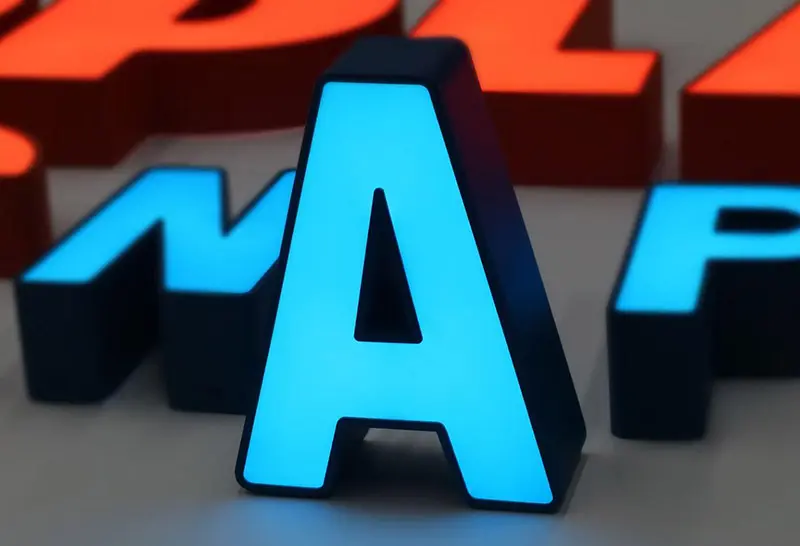

Scenario 1: Design of three-dimensional character signage in shopping malls:

3mm stainless steel surround + 5mm translucent acrylic panel

Built-in 2835 model LED light strip (spacing 3cm)

Energy saving effect: 82% lower energy consumption than traditional neon lights, and life extended to 62,000 hours

Scenario 2: Intelligent upgrade of dynamic guidance in parking lots:

Access to the parking space management system, LED luminous signs display the parking space status in real time

Automatically switch to 30%/100% brightness mode in different time periods

Cost recovery: The cost of intelligent transformation can be recovered through power saving in 2.3 years

Common installation misunderstandings and solutions

Misunderstanding 1: Dark areas appear on the edge of the sign

The root cause of the problem: The spacing between the light strips is too large, resulting in uneven light coverage.

Professional countermeasures: Dynamically adjust the light strip density according to the thickness of the translucent panel. When using a 3mm acrylic panel, the interval between the light strips should be controlled within 4cm; if a 5mm thick panel is used, the maximum spacing can be relaxed to 6cm. At the same time, it is recommended to use a 45° angle installation to enhance side light compensation.

Misunderstanding 2: Some modules are not lit after power on

High frequency inducement: positive and negative poles are connected in reverse or voltage fluctuations exceed the tolerance range of the equipment.

Solution steps:

Use a multimeter to detect the impedance value of the fault loop, the normal range should be 5-20Ω

Install a voltage-stabilized power supply module to strictly control the voltage fluctuation within ±5%

Seal all wiring terminals with waterproof glue

Misunderstanding 3: Water accumulates inside the outdoor sign

Typical error: The drainage hole design is missing or maintenance is not timely, causing blockage.

Systematic solution:

Drainage holes with a diameter of 6mm are opened every 50cm at the bottom of the sign box

304 stainless steel insect-proof filter (mesh size ≤1mm) is installed at the hole

Drainage channels need to be cleared with a high-pressure air gun before the rainy season

Advanced skills: the balance between energy saving and aesthetics

1. Light efficiency upgrade: laser dotting technology for light guide plates

The brightness uniformity of LED light-emitting signs is increased to 95% through micron-level concave dot design

Case: After the transformation of an airport sign, the lumen value per unit area increased by 40%, and the power consumption remained unchanged

2. Material mix and match: hidden skills to reduce energy consumption

Metal hollow characters + side-emitting LED: use the reflective properties of metal to reduce the use of light strips by 30%

Double-layer acrylic sandwich design: enhance visual thickness through light refraction and reduce the need for back fill light.

If you are interested in LED illuminated letter customization, welcome to contact us for more information.Contact us