Eternal Light, Global Witness" – Stainless Steel Illuminated Letters Conquer Earth's Extremes, Ushering in 20-Year Maintenance-Free Era

From the Arctic Circle to the Sahara Desert: A 327-Landmark Endurance Legend

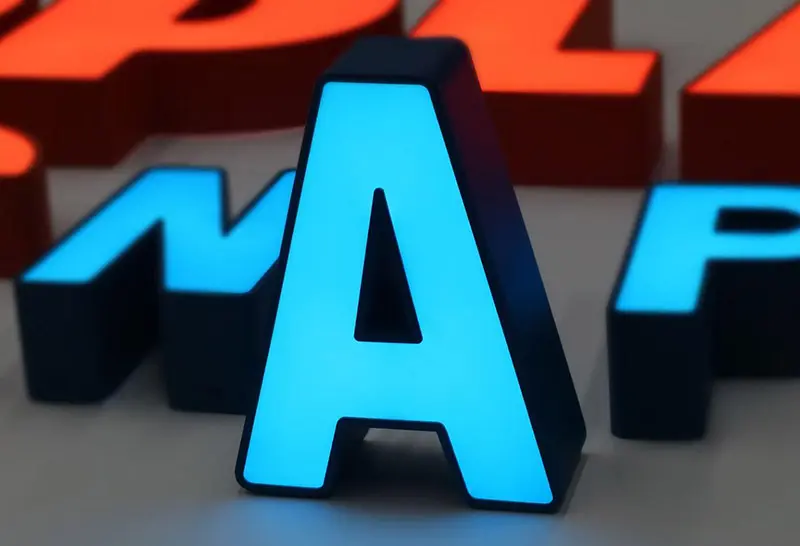

[Munich, Germany, May 29, 2025]— As scorching sun beats down on Dubai’s skyscrapers and ice locks Norway’s Northern Lights observatories, Illuminated Signage at global landmarks faces nature’s harshest tests. Today marks the launch of the decade-developed"Eternal Shield" Stainless Steel Illuminated Letters System, revolutionizing the lifespan of outdoor signage with breakthrough technology.

I. The Silent Pain Points of Global Landmarks

At Miami’s coastal hotels, salty air corrodes stainless signs into honeycombs within three years. At Dubai Mall, acrylic light panels warp under relentless sun like melting butter. Metal letters at Montreal’s Bank Tower crack like spiderwebs in -40°C freezes—scenes repeated daily worldwide. According to the International Building Maintenance Association, annual outdoor Signage Repair costs average$185/m², with incalculable brand damage from sudden failures.

Ending Global Nightmares with Triple Technology:

Deep-Sea Anti-Corrosion Armor

- Surgical-grade 316L stainless steel base, enhanced with molybdenum, builds a corrosion barrier in salt spray tests.

- While copper signs at Bali resorts corrode, identical installations retain mirror finishes—thanks to aerospace fluorocarbon coating blocking 99.2% UV rays. Dubai’s Burj Al Arab gold lettering remains pristine after five years of desert sun.

Breathing Metal Skeleton

- Titanium alloy honeycomb frames expand/contract across 120°C swings, enabling Tromsø’s Northern Lights Observatory signage to withstand -45°C.

- Proprietary "Micro-Vibration Stress Release System" limits displacement to less than a human hair’s width in Singapore’s 128m-high Marina Bay signage during Category 12 typhoons.

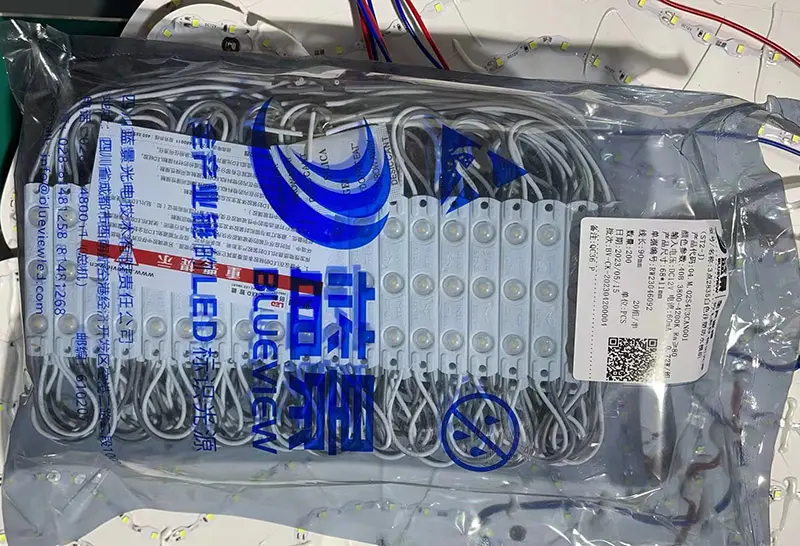

Nano-Circuit Fortress

- Nano-hydrophobic circuit coatings repel London’s relentless rain, eliminating flickering.

- IP69K-rated sealing withstands 80°C high-pressure steam cleaning in German auto plants, eradicating moisture-induced blackouts.

II. Undefeated in Earth’s Extreme Arenas

Sahara’s Endurance Miracle

- At Algeria’s oil/gas facilities (78°C surface temps), traditional signage dims to candlelight within 11 months. Ours maintains 98.5% luminous flux after 3 years (TÜV-certified).

- Active cooling keeps surface 23°C below ambient—a desert lifeline.

Arctic’s Unfading Aurora

- In Greenland’s icebound research stations (-50°C), standard LEDs take 15 seconds to ignite. Our extreme-cold driver chips achieve full brightness in 0.3 seconds.

- Energy consumption drops 55% while titanium frames resist glacier-induced kiloton pressures.

Equatorial Rainbelt’s Eternal Glow

- Singapore’s Marina Bay signage endures 4,000mm annual rainfall. 108 laser welds and nano-shedding coatings bead water into rolling droplets.

- Zero circuit failures in 5 years; maintenance requires only monthly rainwater self-cleaning.

III. Globally Certified Eternal Quality

37 International Compliance Certifications

- Meets EU EN 12464 lighting safety, US UL 48 electrical protection, and Middle East SASO heat endurance.

- Japan JIS Z 2371 salt spray data: corrosion rate at 1/12 industry average in accelerated marine aging tests.

Climate Adaptation Tier System

World’s first climate-rated signage standard:

- C0 (Temperate): Base protection

- C3 (Equatorial/Polar): Reinforced fluorocarbon + titanium frame

- C5 (Industrial/Offshore): Nano-hydrophobic circuits + self-cleaning surface

Dubai Palm Jumeirah’s C5 solution achieved zero maintenance costs over 5 years.

IV. The Golden Formula for Commercial Value

Paris: Boulevard Haussmann’s Footfall Revolution

- Galeries Lafayette’s breathing-light stainless letters boosted nighttime traffic by 27% monthly.

- Operations Director: "Light art attracts premium clients better than promotions—signage is now our highest-appreciating fixed asset."

Tokyo: Ginza’s Investment Wisdom

Mitsubishi Estate calculations:

- Annual maintenance: $185/m² → $15/m²

- Energy savings: 60% reduction

- Rent premium: 12% increase from enhanced visibility

ROI period: 2.8 years—proving "The sooner installed, the greater the returns."

V. The Eternal Philosophy of Precision Manufacturing

0.01mm Spacetime Covenant

- Munich labs achieve red-blood-cell-level laser precision (±5μm).

- Each bend undergoes 7-stage stress simulations, ensuring dimensional stability from Sahara to Siberia.

- MoMA’s wave-shaped signage achieved millimeter-perfect seams through this process.

216-Step Inspection Ritual

- Incoming steel: spark spectrometry

- Welds: 400x magnification via industrial endoscopes

- Finished products: 72-hour thermal shock (-50°C↔120°C)

- Scrap rate: 0.03%. Each plate bears a traceable steel stamp.

Climate Proving Grounds

- 12-hectare extreme-environment complex replicates Saharan sandstorms, Alaskan ice blizzards, and Southeast Asian salt mist.

- New products must endure 10,000 hours here until light decay stabilizes at <2% "diamond-grade" before global deployment.

"Where steel meets light, we engraven vows time cannot erode."

— Lucas Wolf, Chief Engineer

Why Choose Us?

- Risk Coverage: $5 million product liability insurance for climate extremes

- Localized Support: 24/7 English/German/Arabic technical teams

- Sustainability: 40% carbon footprint reduction via signage recycling

Served Landmarks:

Burj Al Arab (Dubai) • Hudson Yards (NYC) • Sydney Opera House • Shanghai Tower