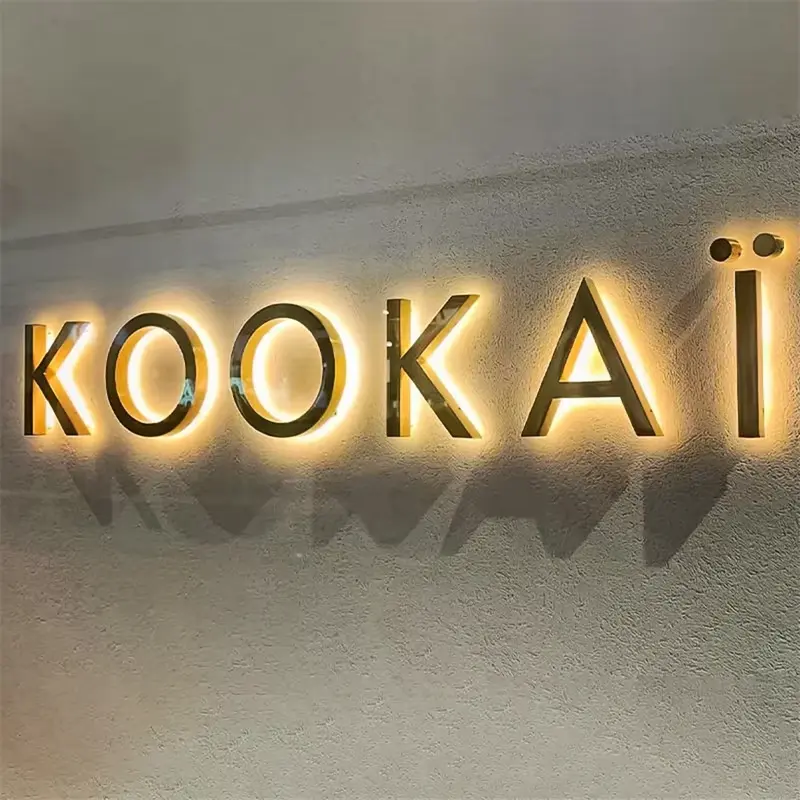

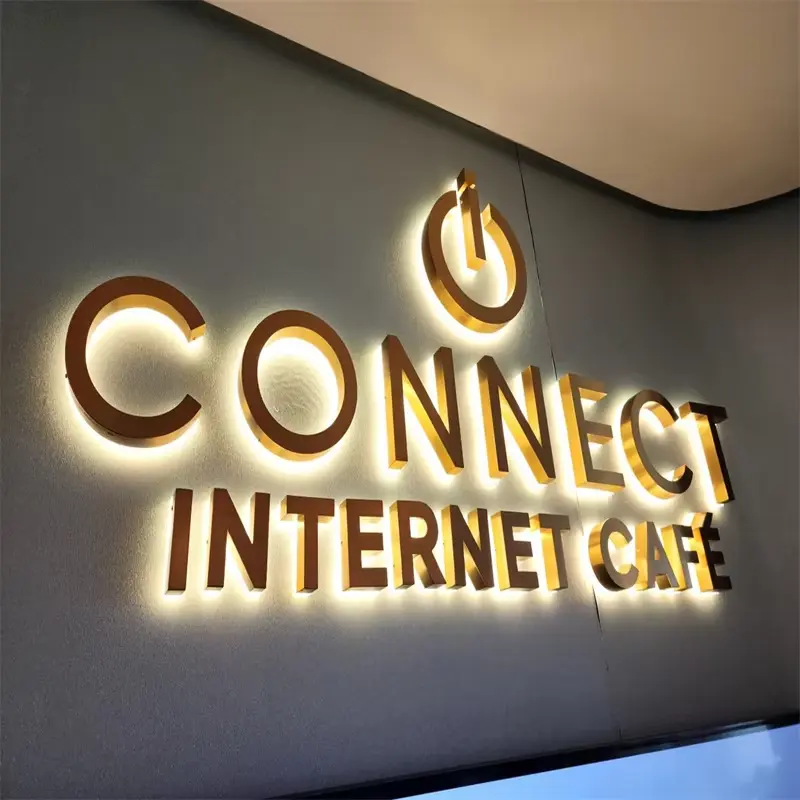

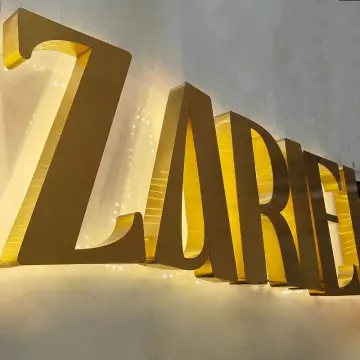

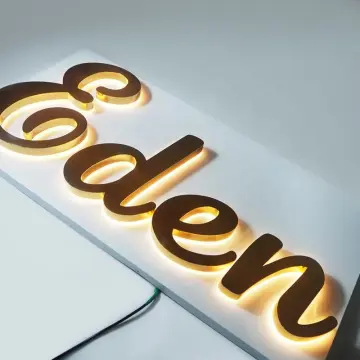

Mirror Gold 3D Backlit Sign Letters Luxury Halo Effect for Storefront

Another issue we see with cheap imports is the "shadow gap." If the LEDs are spaced too far apart inside the letter, you get dark spots in the halo. We don't cut corners here. We use high-density LED strips (typically 60 to 120 chips per meter) arranged in a tight zigzag pattern. By packing the LEDs closer together, we ensure the light overlaps perfectly before it even leaves the shell. It guarantees that smooth, continuous ribbon of light that makes a backlit letter look premium rather than like a connect-the-dots project.

Finally, we have to talk about reliability. Electronics usually fail in the first 48 hours if they have a manufacturing defect. We don't want that happening on your building. So, once your sign is assembled, we move it to our "Aging Room." We power up every backlit letter and leave it running at full brightness for a continuous 72-hour burn-in cycle. We monitor the temperature and color consistency. If a module is going to fail, we want it to fail here in the shop, so we can replace it before it ever gets packed into the crate.

Case Picture