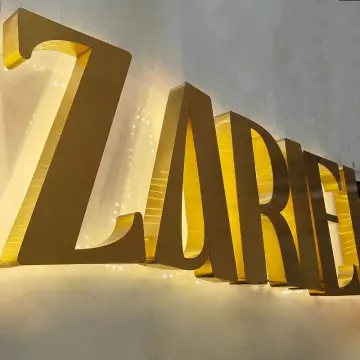

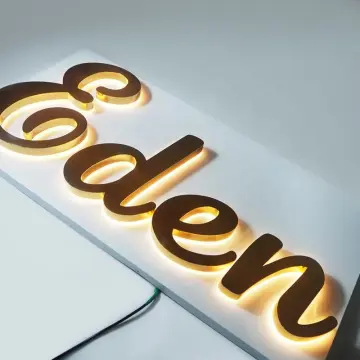

Luxury Electroplated Brass Backlit Signs for Corporate Offices

Regarding "Material Synthesis," let's get specific about the resilience you described. To actually achieve a 100,000-hour lifespan, the LEDs need a cool environment. We mount the diodes on Metal Core PCBs (MCPCB) which are bolted directly to the aluminum body of the backlit letter. This turns the entire sign into a passive heat sink, efficiently conducting heat away from the chips. For the exterior finish, we adhere to the AAMA 2604 high-performance coating standard. This ensures the finish of the backlit letter resists chalking and UV fading for years, maintaining that "architectural permanence" even in harsh sunlight.

Finally, for "Contextual Intelligence," we focus on the interaction with the substrate. A backlit letter behaves differently on rough brick than it does on smooth glass. We adjust the mounting hardware—the "standoffs"—to the millimeter based on your wall texture. A rough surface requires the backlit letter to sit further out (perhaps 40mm) to allow the light to wash over the texture without creating shadows. We also match the LED Kelvin temperature (e.g., 3000K Warm vs. 5000K Cool) to align with the building’s existing lighting narrative, ensuring the backlit letter feels like an intrinsic, organic part of the structure.

Case Picture