Large Scale Architectural Backlit Letters for Building Exterior Names

Let’s talk about cutting the metal. Old-school plasma cutters or CO2 lasers generate too much heat. This burns the edges of the stainless steel, leaving a brown scorch mark that you can see even after painting. We use a High-Power Fiber Laser with Nitrogen assist. The nitrogen gas cools the cut instantly, preventing oxidation. This means the edge of every backlit letter comes off the table cool to the touch and surgically clean. It is the only way to guarantee that the paint will adhere properly to the edge of the backlit letter without peeling off later.

Post-installation care is where many business owners accidentally destroy their own signs. You must never use standard glass cleaners (like Windex) to clean the back of a backlit letter. Why? Because they contain ammonia. Ammonia attacks the molecular structure of acrylic, causing "crazing"—thousands of tiny micro-cracks that make the plastic look like shattered glass. We include a "Care Kit" with every order, instructing your cleaning crew to use only mild soapy water or specific plastic polishes on the backlit letter, protecting your investment from chemical damage.

Finally, how do you turn it on? Old photocell sensors are unreliable; they get covered by snow, dirt, or bird droppings, causing the sign to stay dark at night or turn on during the day. We recommend installing an Astronomic Timer for your backlit letter system. Unlike a sensor, this digital chip calculates the exact sunset and sunrise times for your specific GPS latitude and longitude, adjusting automatically every day of the year. Your backlit letter will turn on precisely at dusk, 365 days a year, without you ever having to touch a switch or clean a dirty sensor.

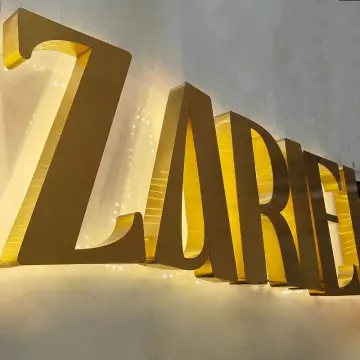

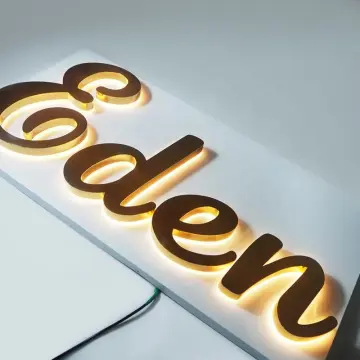

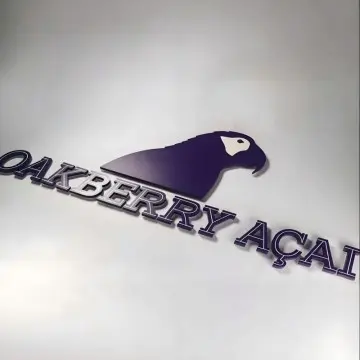

Case Picture