Electroplated Chrome Polished Backlit Letters with Cool White LED

A year after installation, you often see ugly black streaks running down the wall from underneath a sign. This is caused by road dust settling on top of the letter and then washing down with the rain. To save your building’s facade, we can install a hidden EPDM rubber gasket or a "standoff washer" behind the backlit letter. This pushes the unit slightly off the wall, creating a gap that allows dirty rainwater to drip clear of the facade surface. It prevents that "crying eyes" look where a dirty streak runs down from every backlit letter on the storefront.

If your business is in a city with heavy traffic or industrial smog, you need to worry about Sulfur. Exhaust fumes contain sulfur, which penetrates standard LEDs and turns the internal silver reflector black. This kills the light output in months. For urban projects, we specify "Anti-Sulfuration" LEDs for every backlit letter. These chips have a special gold or ceramic coating that creates a hermetic barrier against chemical gases. It guarantees that the light inside a backlit letter stays bright white, even in the middle of a polluted downtown district.

Finally, let’s talk about mounting on luxury stone. If you try to use a standard hammer drill to make a wire hole in marble or granite, you will crack the slab. The vibration is too violent. We advise all our installers to use "Diamond Core Bits" when mounting a backlit letter on natural stone. This bit grinds a hole rather than punching it. We even supply a water-cooling guide. It takes longer, but it ensures you get a clean, polished hole for the backlit letter wire without shattering a $5,000 piece of facade stone.

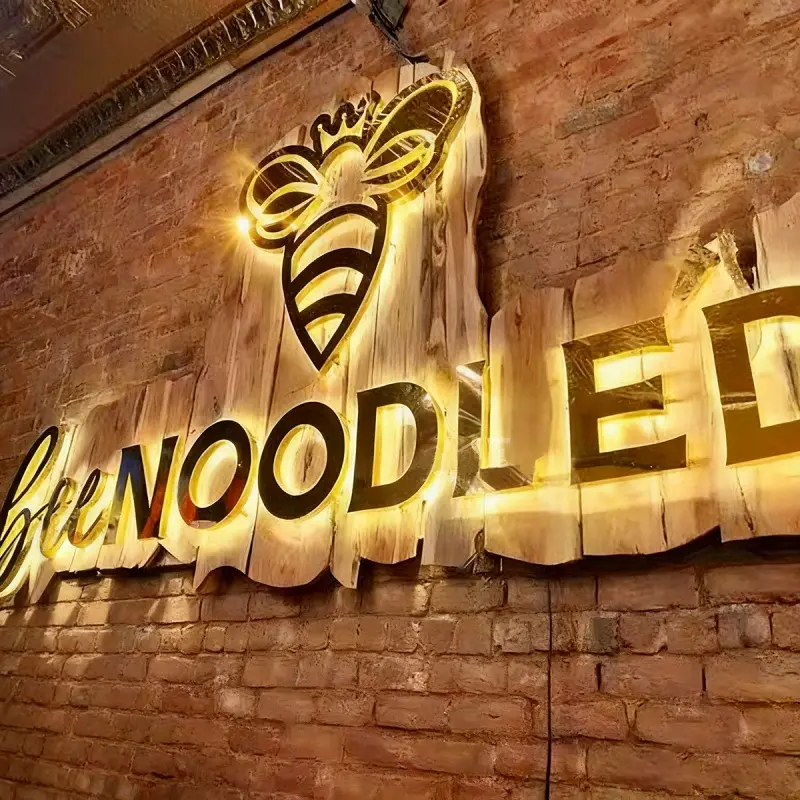

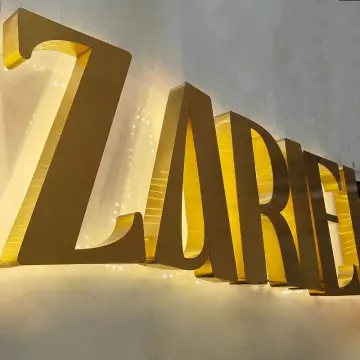

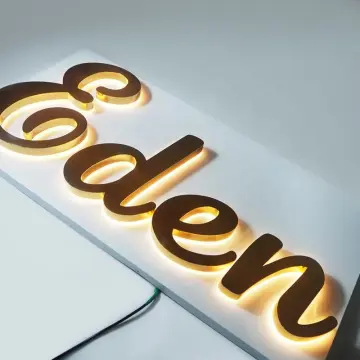

Case Picture