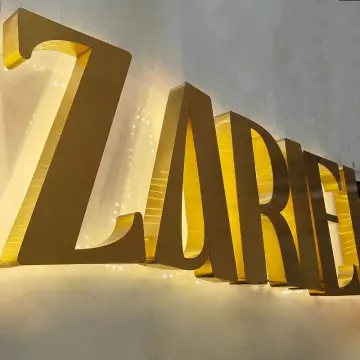

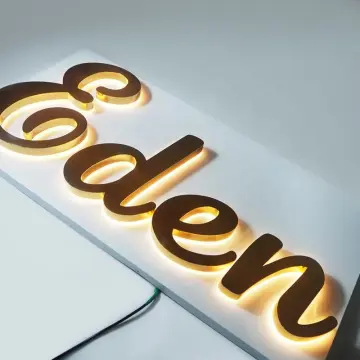

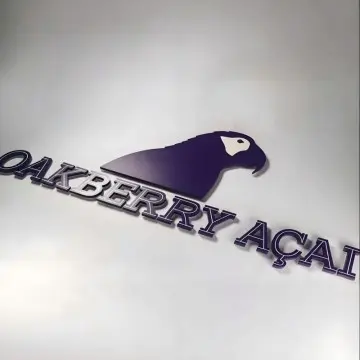

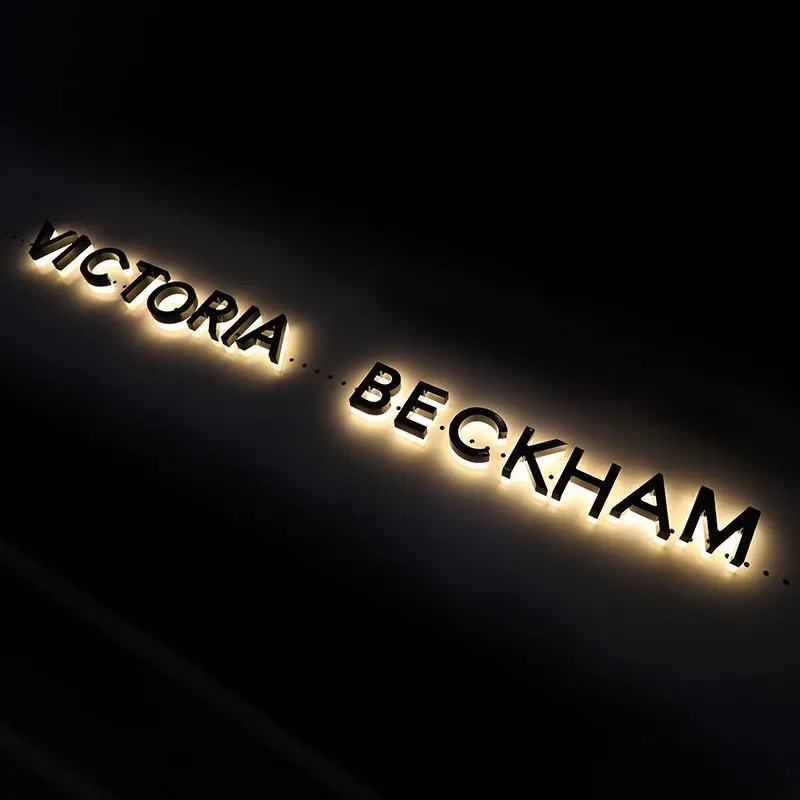

Custom Made Painted Metal Backlit Letters for Shop Front Signs

Manufacturing reliability often comes down to how the LEDs are connected. Hand-soldering is risky because humans get tired. If the soldering iron isn't hot enough, you get a "cold solder joint." It looks fine initially, but after a few months of thermal expansion, the joint cracks and the power cuts out. We use machine-automated "Reflow Soldering" for the LED modules inside every backlit letter. The machine heats the entire assembly in an oven, melting the paste evenly. It creates a molecular bond that is virtually unbreakable, ensuring the backlit letter stays lit even in vibrating environments like train stations.

Let’s talk about "Lifespan." Everyone claims 100,000 hours, but that is misleading. LEDs don't just burn out like lightbulbs; they slowly get dimmer. The industry standard is "L70," which measures how long it takes for the light to lose 30% of its brightness. Cheap chips hit L70 in just two years. We source Tier-1 diodes where the L70 rating exceeds 60,000 hours. This ensures that the backlit letter you install today won't look like a dim, tired version of itself five years down the road. You are paying for sustained brightness, not just initial impact.

Finally, a note on installation surfaces. Many modern buildings use ACP (Aluminum Composite Panel) or "Alucobond." This material is very thin—usually two sheets of aluminum sandwiching a plastic core. If you just use normal screws, the weight of a heavy backlit letter will eventually strip the threads and rip out. For ACP facades, we use spring-loaded "Toggle Bolts" or "Butterfly Anchors." These expand behind the wall panel, spreading the load over a larger area. It guarantees that your backlit letter stays securely mounted, even if the facade material itself is only 4mm thick.

Case Picture