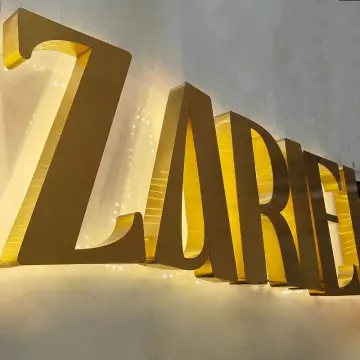

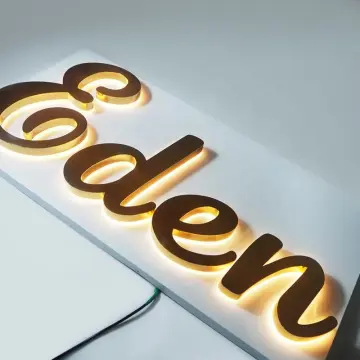

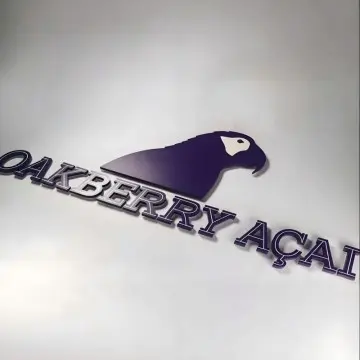

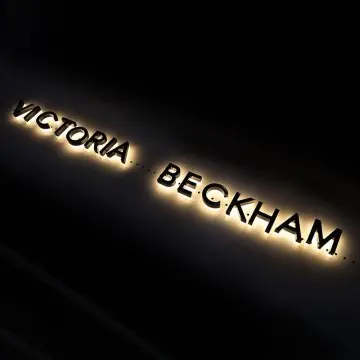

Custom Acrylic Led Sign 3d Letter Sign Print Frontlit Metal Sign Electronic Sign

We mentioned weep holes for drainage before, but here is a nuance: if you just drill a hole in the bottom, light will shoot out of it like a laser beam, creating an ugly spotlight on the ground below the sign. To fix this, we weld a small internal "Light Baffle" or shield over the drain hole inside the backlit letter. This Z-shaped metal piece allows water to flow around it and exit, but it completely blocks the line-of-sight for the light. It ensures that the only glow coming from your backlit letter is the halo on the wall, not a distracting drip of light on the floor.

Let's talk about paint chemistry. Powder coating is great for durability, but it has an "orange peel" texture. If you want a mirror-smooth, high-gloss finish (like a Ferrari), powder coat can't do it. For these high-end projects, we use 2-Component Automotive Polyurethane (PU) Paint. It is chemically cured and offers incredible flexibility. If a stone hits the backlit letter, PU paint tends to dent rather than chip or shatter like hard powder coating does. It keeps the face of the backlit letter looking pristine even in harsh highway environments.

Finally, there is the "T-Feed" wiring method. Most people wire a sign in a single long chain (Series). The problem is, by the time the electricity gets to the last backlit letter, it has lost voltage, making the end of the sign look dim. Instead of just using thicker wire, we use a "Center Injection" or T-Feed topology. We run the main power cable to the middle backlit letter in the word, and split the power left and right. This cuts the resistance distance in half, guaranteeing that the first letter and the last letter are identically bright to the naked eye.

Case Picture