Custom 3D Backlit Stainless Steel Letters Business Logo Signage

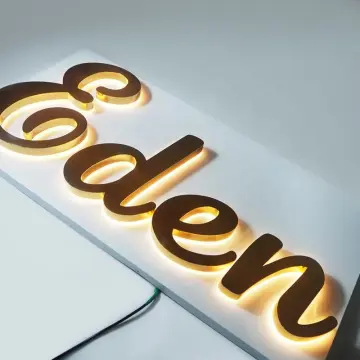

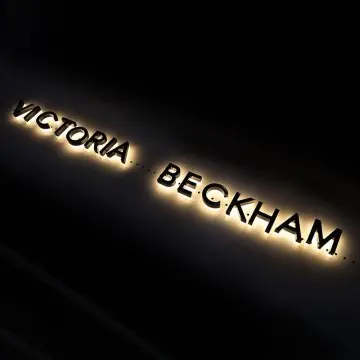

Another detail that separates a pro sign from a DIY kit is how we handle power. If you have a long brand name, you might notice the first letter is bright, but the last letter looks a bit dim. That is called voltage drop. It happens when the copper wire is too thin or the run is too long. We solve this by running a "main line" bypass or feeding power from both ends of the sign using 18AWG pure copper wiring. We make sure every single letter gets the full 12 volts it needs to shine at 100% brightness.

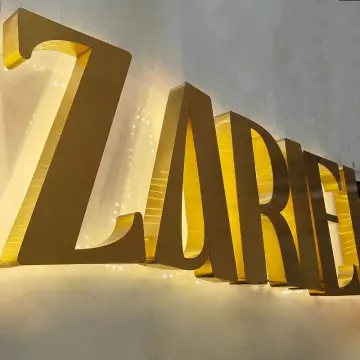

For the metal finish, we offer something better than standard paint. If you want a metallic look, we use Titanium Electroplating on stainless steel. Whether you want a Mirror Gold, Rose Gold, or Brushed Black finish, electroplating bonds the color to the metal at a molecular level. Unlike spray paint which can scratch off during installation, titanium plating is incredibly hard and looks like real jewelry.

Lastly, let's talk about maintenance. Most factories glue the back panel shut to save time. We don't. We use small, discreet screws to secure the acrylic back. Why? Because even the best LEDs might fail after 5 or 8 years. If we glued it, you would have to throw the whole sign away. With our design, you can simply unscrew the back, swap out the LED module, and your sign is good for another decade. It is a repairable, long-term asset for your building, not a disposable plastic toy.

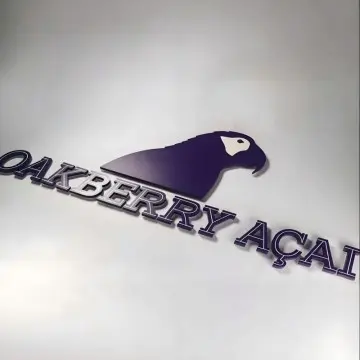

Case Picture