Brushed Silver Reverse Lit Backlit Signs with Warm White LED

Now, let’s talk about vibration. If your business is near a busy road or a train line, the constant rumble can slowly unscrew the hardware on your sign. To prevent parts from rattling loose, we apply a drop of Blue Threadlocker (like Loctite) to the mounting studs of every backlit letter before we ship it. It is a liquid adhesive that cures into a hard plastic, locking the threads in place. It guarantees that the back panel of your backlit letter won't vibrate loose and fall on a customer’s head during a windy storm.

For commercial clients with large installations, electricity bills matter. Standard power supplies have a low "Power Factor," meaning they waste energy as heat. We use High-PFC (Power Factor Correction > 0.95) drivers. This makes the electrical draw of the backlit letter extremely efficient. If you have a massive brand logo with twenty letters, switching to High-PFC drivers can save you significant money on your monthly utility bill compared to running a standard backlit letter setup that wastes reactive power.

Finally, inspect the paint texture. A common defect in powder coating is the "Orange Peel" effect, where the paint looks bumpy like the skin of a citrus fruit. This happens when the spray gun pressure is wrong or the curing oven is too hot. We hand-sand our metal shells between coats to ensure the face of the backlit letter is perfectly smooth. Whether you choose a matte black or a glossy red, the surface of our backlit letter will look like a polished car body, not a bumpy fruit. It is a level of finish that stands up to close inspection at eye level.

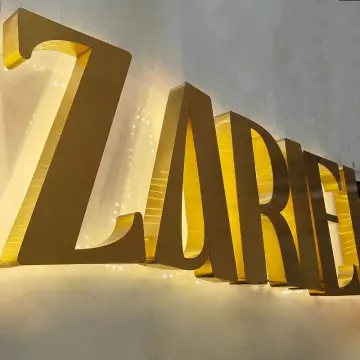

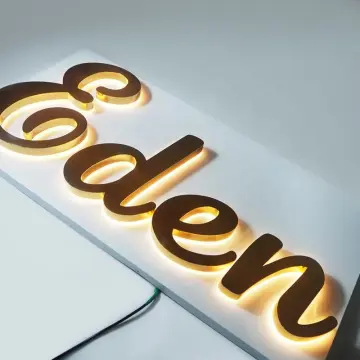

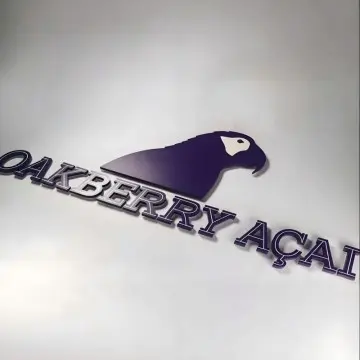

Case Picture